CNC Swiss Type Lathe

CNC Swiss Type Lathe

SS-12RB/RBY

Compact Swiss-type CNC lathes designed for high-precision machining of small-diameter components. Featuring robust construction, advanced control systems, and optional Y-axis capability (SS-12RBY), these models deliver exceptional accuracy, smooth surface finishes, and efficient cycle times for industries such as medical devices, electronics, and precision engineering.

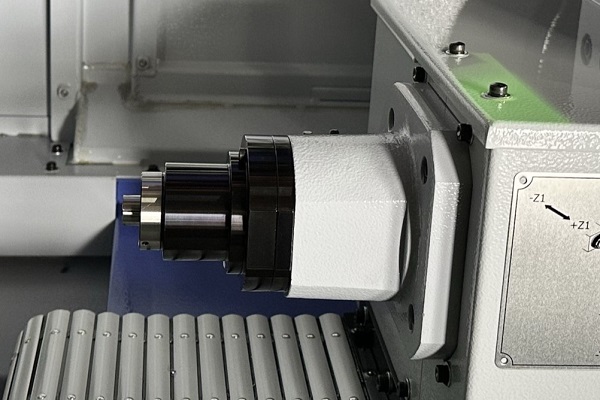

Sub-Spindle

Equipped with a sub-spindle for back-end machining, allowing complete part processing in a single setup. This feature reduces handling time, improves machining accuracy, and increases productivity, making it ideal for complex, multi-operation components.

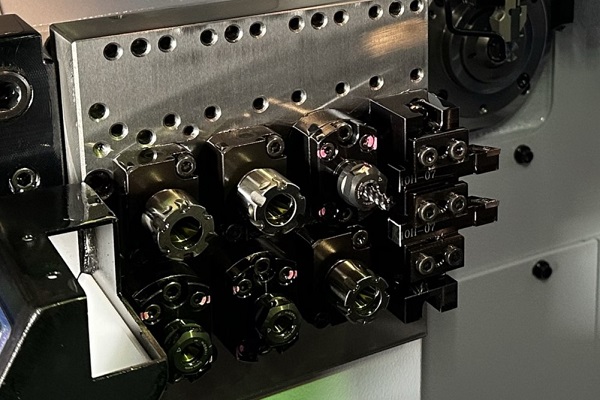

Sub-Spindle Tooling System

Features a dedicated sub-spindle tooling system designed for efficient back-end machining. This configuration supports multiple live and fixed tools, enabling drilling, tapping, and milling operations without removing the workpiece. The rigid tool mounting and precise alignment ensure superior accuracy, shorter cycle times, and enhanced productivity for complex parts.

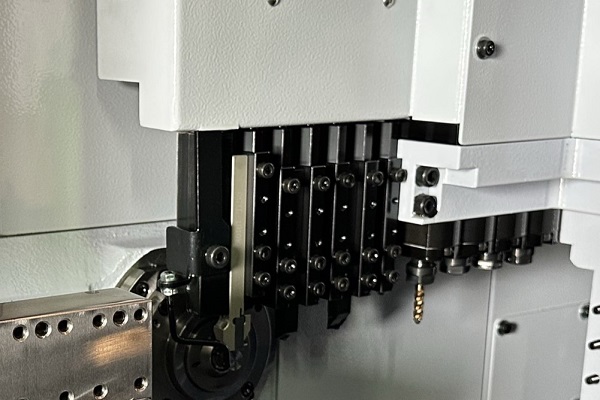

6-position O.D. tooling holder

With a 6-position O.D. tooling holder for efficient external turning operations. This configuration allows multiple tools to be set up simultaneously, reducing tool change time and improving machining productivity. The rigid design ensures stability, accuracy, and consistent surface finish, even under continuous production.

| ITEM | Unit | SS-12RB | SS-12RBY |

|---|---|---|---|

| Main Spindle Max. Turning Diameter | mm | 12 | 12 |

| Sub Spindle Max. Turning Diameter | mm | 12 | 12 |

| Max. Turning Length (rotating bush) | mm | 150 | 150 |

| Max. Turning Length (non bush) | mm | 36 | 36 |

| Max. Turning Length (fixed bush) | mm | 150 | 150 |

| Main Spindle Max. Drilling / Tapping Capacity | mm | Ø8/M6 | Ø8/M6 |

| Sub Spindle Max. Drilling / Tapping Capacity | mm | Ø6/M5 | Ø6/M5 |

| Max. Crossing Drilling / Tapping Capacity | mm | Ø5/M4 | Ø5/M4 |

| OD Tool holder | pcs | 6/▢10mm | 6/▢10mm |

| ID Tool holder | pcs | 4/Ø20mm | 4/Ø20mm |

| S1 Cross Live Tool Holder | pcs | 5 | 5 |

| Sub Spindle Face Live Tool Holder | pcs | 4 | 8 |

| Control Axis (with C axis) | pcs | 7 | 8 |

| Main / Sub Spindle Max. Speed | rpm | 12000 | 12000 |

| Rapid Traverse | m/min | F: 30 / M: 24 | F: 30 / M: 24 |

| S1 Cross Drilling Max. Speed | rpm | 8000 | 8000 |

| S1 Cross Driven Motor | kW | 1 | 1 |

| S2 Face Driven Motor | kW | 1 | 1 |

| S2 Face Drilling Max. Speed | rpm | 8000 | 8000 |

| Main Spindle Motor | kW | 2.2/3.7 | 2.2/3.7 |

| Sub Spindle Motor | kW | 1.0/1.2 | 1.0/1.2 |

| X1/Z1 Motor | kW | 1.4 | 1.4 |

| Y1/X2/Z2 Motor | kW | 0.75 | 0.75 |

| Y2 Motor | kW | Non | 0.75 |

| Coolant Pump | kW | 0.54 | 0.54 |

| Power Requirements | KVA | 20 | 20 |

| Lubrication Capacity | L | 2 | 2 |

| Coolant Tank Capacity | L | 115(100%) | 115(100%) |

| Machine Dimension ( L x W x H) | mm | 2106x1035x1800 | 2106x1035x1800 |

| Weight | KG | 2205 | 2205 |

STANDARD ACCESSORIES

- - External tool holder (6 tools)

- - Inner tool holder (4 tools)

- - Cross drilling tool holder (5 tools)

- - Parts catcher and conveyor

- - Tools & tool box

- - Lighting device

- - Non guide bushing holder or fixed guide bushing holder

- - Spindle servo motor

- - Main spindle C axis

- - Sub spindle C axis

- - Cutting coolant device

- - Cutting coolant inspection

- - Cut-off inspection

- - Lubrication device

- - Sub spindle

- - Sub spindle tool holder for 4 position eccentric & drilling (SS-12RB)

- - Sub spindle tool holder for 8 position eccentric & drilling SS-12RBY

- - Y2 axis (SS-12RBY)

- - Fixed tool holder (sub spindle ER-16)(SS-12RB: 2pcs / SS-12RBY: 3pcs)

- - Rotary tool holder (sub spindle ER-16)(SS-12RB: 2pcs / SS-12RBY: 3pcs)

- - 3 position OD tool holder (sub spindle □10)

- - Chuck gripper (2pcs)

- - Machining room with safety lock

- - Guide bush (1pcs)

- - Spindle collet (2pcs)

- - Operation manual

- - NC operation manual

- - NC maintenance manual

OPTIONAL ACCESSORIES

- - ER 16 M2 Double sided inner tool holder

- - Simultaneous rotary guide bushing holder

- - Long parts catcher (Sub spindle)

- - Chip conveyor & cart

- - ER16 collet set

- - ER11 collet set

- - Cutting oil chiller

- - Collet spring

- - Chuck gripper

- - Stationary tool holder (sub spindle Ø20)

- - Stationary tool holder (sub spindle ER-16)

- - Rotary tool holder (sub spindle ER-16)

- - Whirling threading unit (without inserts and insert holder)

- - Power driven saw unit (main spindle)

- - Power driven saw unit ( sub spindle)

- - 3 position angle drilling tool holder (manual adjusting)

- - 1 position cross live tool (sub spindle)

- - 1 position OD tool holder (sub spindle)

- - Voltage stabilizer

- - Transformer

- - Oil mist collector

- - High pressure coolant system 15/50/100 bars (with sub-coolant tank)

- - Hydraulic bar feeder

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm