HM-43T

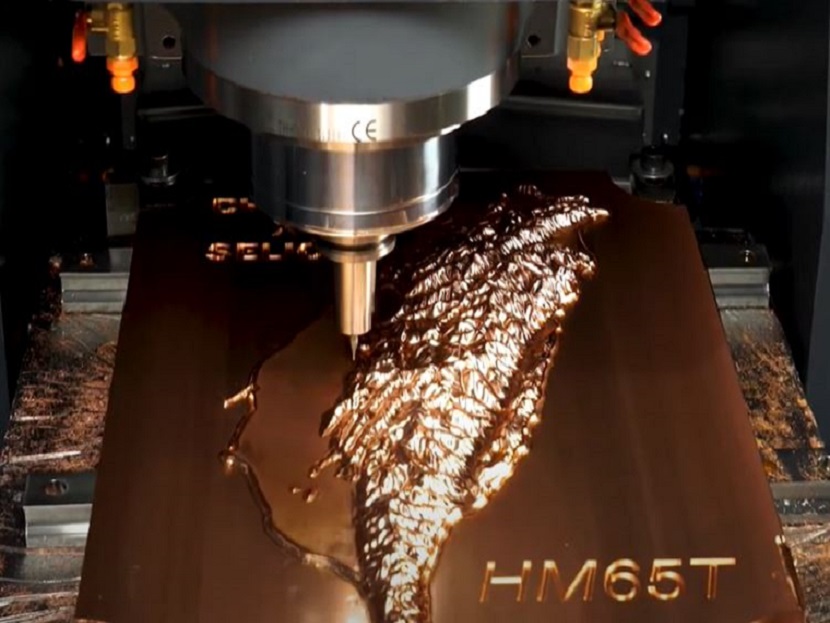

Application: graphite electrode, mold making, build-in high speed spindle, double column machining center.

Gantry Structure Design

The best and rigid design by FEA(Finite Element Analysis) to optimize the gantry structure of high rigidity and heavy loading for the machining stability.

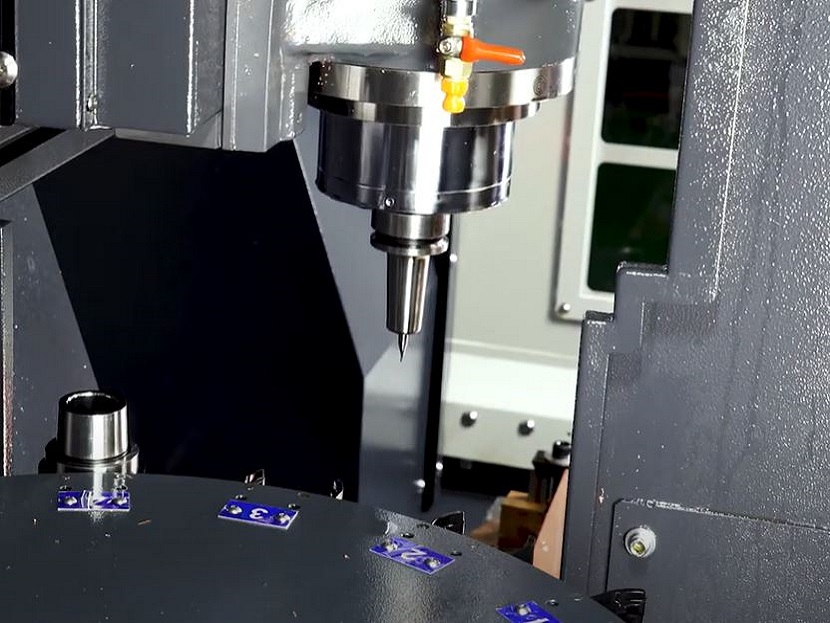

The Spindle Thermal Error Compensation

Compensate for the difference in heat distortion through the spindle thermal detection to achieve highly accurate cutting

Ball Bar Calibration

Renishaw ball bar testing used to test and record each machine's X and Y simultaneous movements.

This guarantees ideal and accurate table movement and ball screw backlash.

This guarantees ideal and accurate table movement and ball screw backlash.

| Model | Units | HM43T |

|---|---|---|

| Spindle speed (max.) | RPM | 3000-30000 |

| Spindle taper | - | ISO25 (ER20) |

| Spindle motor (S1/S6) | KW | 4/5 |

| Woking table size | mm | 500x400 |

| T-slot | mm | 14x4x100 |

| Max. load of table | kg | 200 |

| Travel (XxYxZ) | mm | 400x300x200 |

| Dist. from table surface to spindle nose | mm | 100-300 |

| Work feed | M/min | 10 |

| Rapid traverse (X,Y,Z) | M/min | 15 |

| X.Y.Z. axis servo motor | - | AC servo motor |

| Total power consumption (max.) | KAV | 11 |

| Net weight | kg | 2680 |

Standard Accessories

- Work Lamp 1set

- Tool Kit 1set

- Coolant Equipment 1set

- Spindle Air Blast (for ATC) 1set

- Manual Pulse Generator (MPG) Hand Wheel 1SET

- Spindle Central Lubrication System (for ATC) 1set

- Cutting Air Blast 1set

- Working Alarm Indicator 1set

- Heat Exchanger for Electrical Cabinet

- Automatic Tool Length Measurement 1set

Optional Accessories

- Tool Shank

- Collect

- Pneumatic Freezing Dryer (ATC)

- 4th Axis Rotary Table

- AVR

- Ethernet Card

- X,Y,Z 3-axis Linear Scale

- Precision Optical Scale

- ATC(HM43)

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm