HM-65T

Application: graphite electrode, mold making, build-in high speed spindle, double column machining center.

Co-developed by SELICA and CHMER, built for excellence.

By combining CHMER’s expertise in electrical discharge machining with SELICA’s innovation in CNC solutions, we are pushing the boundaries of performance and reliability, delivering next-generation machine tools designed to meet the most demanding manufacturing needs.

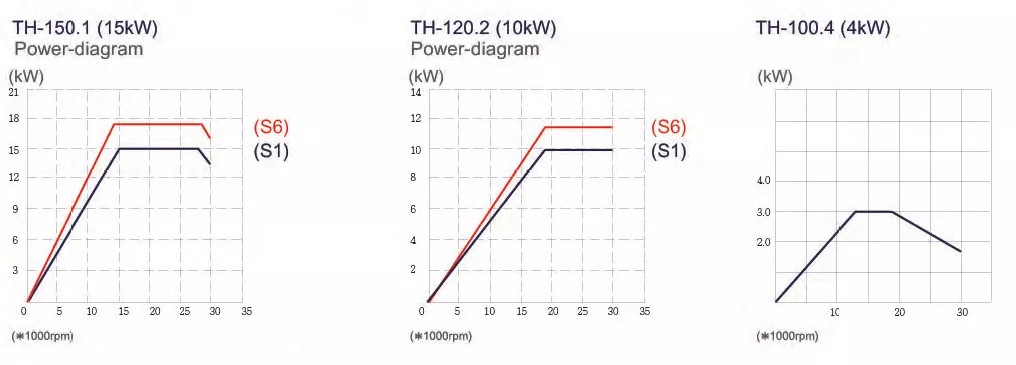

Build-In High Speed Spindle

PMSM-Permanent Magnet Synchronous Motor(Opt.)

PMSM: smaller size, low rpm and high torque, lower thermal emission for less thermal inaccuracy, high and stable cutting accuracy, rapid forward and reverse switch, suitable for more accurate surface workpieces.

PMSM: smaller size, low rpm and high torque, lower thermal emission for less thermal inaccuracy, high and stable cutting accuracy, rapid forward and reverse switch, suitable for more accurate surface workpieces.

| Model | Units | HM65T |

|---|---|---|

| Spindle speed (max.) | RPM | 3000-30000 |

| Spindle taper | - | HSK E40 |

| Spindle motor (S1/S6) | KW | 10/13 |

| Woking table size | mm | 540x650 |

| T-slot | mm | 16x5x100 |

| Max. load of table | kg | 300 |

| Travel (XxYxZ) | mm | 500x600x300 |

| Dist. from table surface to spindle nose | mm | 150-450 |

| Work feed | M/min | 10 |

| Rapid traverse (X,Y,Z) | M/min | 30,30,20 |

| X.Y.Z. axis servo motor | - | AC servo motor |

| Total power consumption (max.) | KAV | 24 |

| Net weight | kg | 4300 |

Standard Accessories

- Work Lamp

- Tool Kit

- Coolant Equipment

- Spindle Air Blast (for ATC)

- Manual Pulse Generator (MPG) Hand Wheel

- Spindle Central Lubrication System (for ATC)

- Cutting Air Blast

- Working Alarm Indicator

- Heat Exchanger for Electrical Cabinet

- Automatic Tool Length Measurement

Optional Accessories

- Tool Shank

- Collect

- Pneumatic Freezing Dryer (ATC)

- 4th Axis Rotary Table

- AVR

- Ethernet Card

- X,Y,Z 3-axis Linear Scale

- Precision Optical Scale

- ATC

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm