CNC Swiss Type Lathe

CNC Swiss Type Lathe

SS-20A/20AS

The SELICA SS-20A and SS-20AS deliver high-precision machining for small-to-medium diameter parts. Featuring a rigid design and advanced controls, the SS-20AS adds a sub-spindle for complete machining in one setup, boosting productivity and accuracy.

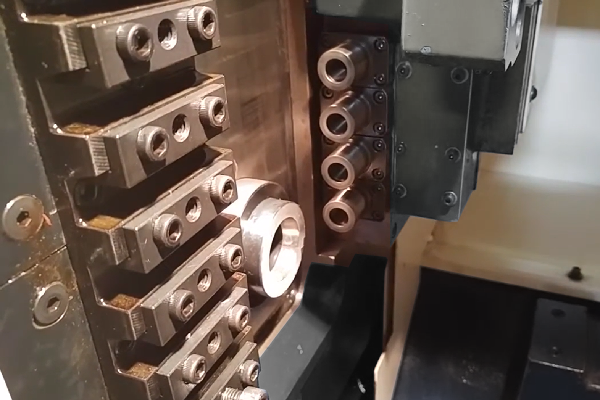

Tooling Capacity

The SS-20A / SS-20AS is equipped with a versatile tooling layout for efficient multi-operation machining:

External Tool Holders: 8 positions for turning and profiling operations.

Inner Tool Holders: 5 positions for boring, threading, and internal machining.

Side Drilling Devices: 4 positions for cross drilling, tapping, and milling operations.

This configuration enables flexible part processing, reduced setup time, and consistent high-precision performance.

External Tool Holders: 8 positions for turning and profiling operations.

Inner Tool Holders: 5 positions for boring, threading, and internal machining.

Side Drilling Devices: 4 positions for cross drilling, tapping, and milling operations.

This configuration enables flexible part processing, reduced setup time, and consistent high-precision performance.

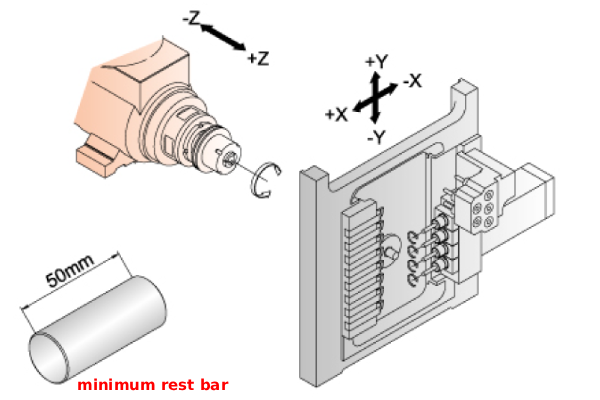

20A Tooling layout

SS-20A is equipped with a single spindle and a flexible guide bush system, allowing operators to choose between guide bush and non-guide bush holders depending on the application. This adaptability provides optimal support for long and slender workpieces when using the guide bush, or reduced material waste when operating without it. The system accommodates a minimum rest bar length of 50 mm, enabling efficient machining while minimizing raw material remnants.

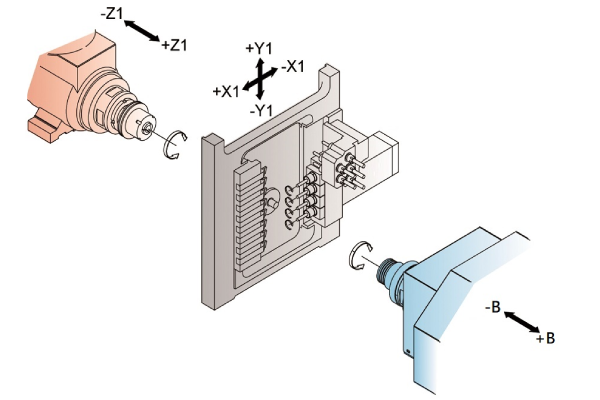

20AS Tooling layout

The SS-20AS is equipped with both a main spindle (Z1 axis) and a sub-spindle (B axis), enabling complete front and back machining in a single setup. Its rigid gang type tooling layout supports multiple turning, drilling, and milling tools, arranged for optimal accessibility and minimal tool change time.

| Model | Unit | SS-20S | SS-20AS |

|---|---|---|---|

| Max. turning dia. of main spindle | mm | 20 | 20 |

| Max. turning dia. of sub-spindle | mm | 20 | 20 |

| Max. turning length (fixed guide bush) | mm | 200 | 200 |

| Max. turning length (rotary guide bush) | mm | 85 | 85 |

| Max. turning length (non guide bush) | mm | 45 | 45 |

| Max. drilling capacity of main spindle | mm | 10 | 10 |

| Max. drilling capacity of sub-spindle | mm | 10 | 10 |

| Max. tapping capacity of main spindle | - | M8 | M8 |

| Max. tapping capacity of sub-spindle | - | M8 | M8 |

| Max. cross drilling capacity | mm | 10 | 10 |

| Max. cross tapping capacity | - | - | M6 |

| No. of external turning tools | pcs | 12 | 8 |

| No. of internal turning tools | pcs | 5 | 5 |

| No. of cross drillings | pcs | - | 4 (optional:7) |

| Size of tool | mm | 12x12x90 | 12x12x90 |

| No. of axis controls | - | 4 (X/Y/Z/B) | 5 (X/Y/Z/C/B) |

| Bore of spindle | mm | 29 | 29 |

| Spindle speed range | rpm | 15-8000 | 15-8000 |

| Rapid traverse X/Z | m/min | 24 | 24 |

| Main spindle motor | kw | 3.7 | 3.7 |

| Sub-spindle motor | kw | 2.2 | 2.2 |

| X1/Z1 motor | kw | 0.5 / 0.75 | 0.5 / 0.75 |

| Y-axis motor | kw | 0.75 | 0.75 |

| Cross drilling motor | kw | - | 0.5 |

| X2/Z2 motor | kw | -/0.5 | -/0.5 |

| Coolant motor | kw | 0.375 | 0.375 |

| Power requirement | kw | 15 | 15 |

| Machine dimensions (LxWxH) | mm | 2045 x 1270 x 2025 | 2045 x 1270 x 2025 |

| Weight | kg | 2125 | 2140 |

- Guide bush

- Non guide bushing holder

- Spindle collet

- Cutting coolant inspection

- Cut-off inspection

- Central lubrication unit

- Parts catcher

- Leveling pads

- Cutting coolant

- Lighting device

- Tool and tool box

- Operation manual

- Fixed guide bushing holder

- Simultaneously rotary guide bushing holder

- Chip conveyor

- Parts conveyor

- Long parts catcher

- 3 position eccentric rotary tool holder

- "ER16 collet chuck (double side) for SS-20S/20AS

- ER16 collet set

- Voltage stabilizer

- Transformer

- Hydraulic bar feeder

- CE certification

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm