CNC Swiss Type Lathe

CNC Swiss Type Lathe

SS-20AB/AST

Application: swiss type lathe, swiss type lathes, cnc swiss lathe, swiss turning machines, medical implant.

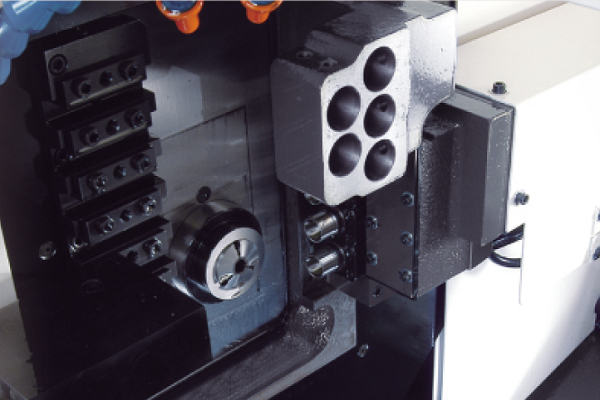

SS-20AB-Tooling

high-precision Swiss-type CNC lathes designed for small-to-medium diameter machining up to Ø20 mm. Both models feature a rigid gang type tooling system with capacity for 8 external tools, 5 internal tools, and 4 cross drilling devices, plus 4 sub-spindle face tools for complete part machining in one setup.

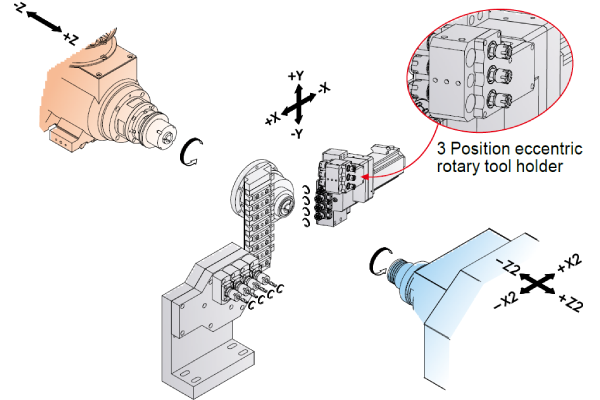

SS-20AB with 3 position eccentric rotary tool holder

The SS-20AB is equipped with a 3-position eccentric rotary tool holder, providing greater flexibility for drilling, tapping, and milling operations. This design allows multiple live tools to be mounted in a compact arrangement, enabling faster tool changes, reduced setup time, and efficient machining of complex features.

| Model | Unit | SS-20AB | SS-20AST |

|---|---|---|---|

| Max. turning dia. of main spindle | mm | 20 | 20 |

| Max. turning dia. of sub-spindle | mm | 20 | 20 |

| Max. turning length (fixed guide bush) | mm | 200 | 200 |

| Max. turning length (rotary guide bush) | mm | 85 | 85 |

| Max. turning length (non guide bush) | mm | 45 | 45 |

| Max. drilling capacity of main spindle | mm | 10 | 10 |

| Max. drilling capacity of sub-spindle | mm | 10 | 10 |

| Max. tapping capacity of main spindle | - | M8 | M8 |

| Max. tapping capacity of sub-spindle | mm | M8 | M8 |

| Max. cross drilling capacity | mm | 10 | 10 |

| Max. cross tapping capacity | - | M6 | M6 |

| No. of external turning tools | pcs | 8 | 8 |

| No. of internal turning tools | pcs | 5 | 5 |

| No. of cross drillings | pcs | 4 (optional:7) | 4 (optional:7) |

| No. of face tool holder of sub-spindle | pcs | 4 | 4 |

| Size of tool | mm | 12x12x90 | 12x12x90 |

| No. of axis controls | - | 7 (X1/Y1/Z1/X2/Z2/C1/C2) | 7 (X1/Y1/Z1/X2/Z2/C1/C2) |

| Bore of spindle | mm | 29 | 29 |

| Spindle speed range | rpm | 15-8000 | 15-8000 |

| Rapid traverse X/Z | m/min | 24 | 24 |

| Main spindle motor | kw | 3.7 | 3.7 |

| Sub-spindle motor | kw | 2.2 | 2.2 |

| X1/Z1 motor | kw | 0.5 / 0.75 | 0.5 / 0.75 |

| Y-axis motor | kw | 0.75 | 0.75 |

| Cross drilling motor | kw | 0.75 | 0.75 |

| Face drilling motor | kw | 0.75 | 0.75 |

| X2/Z2 motor | kw | 0.5 / 0.5 | 0.5 / 0.5 |

| Coolant motor | kw | 0.375 | 0.375 |

| Power requirement | kva | 15 | 15 |

| Machine dimensions (LxWxH) | mm | 2430 x 1420 x 2135 | 2430 x 1420 x 2135 |

| Weight | kg | 2400 | 2400 |

- Guide bush

- Non guide bushing holder

- Spindle collet

- Cutting coolant inspection

- Cut-off inspection

- Central lubrication unit

- Parts catcher

- Leveling pads

- Cutting coolant

- Lighting device

- Tool and tool box

- Operation manual

- Stationary tool holder ($2) x 2 (for SS-20AB)

- Rotary tool holder ($2) x 2 (for SS-20AB)

- Fixed guide bushing holder

- Simultaneously rotary guide bushing holder

- Chip conveyor

- Parts conveyor

- Long parts catcher

- 3 position eccentric rotary tool holder

- ER16 collet chuck (double side) for SS-20AB/20AST

- ER16 collet set

- Voltage stabilizer

- Transformer

- Hydraulic bar feeder

- CE certification

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm