CNC Lathe

CNC Lathe

SH- 75/90 LMML

The SELICA SH series is built for large-diameter machining, offering high rigidity, stability, and precision. Its slant-bed design ensures smooth chip removal and reliable performance under heavy cutting conditions.

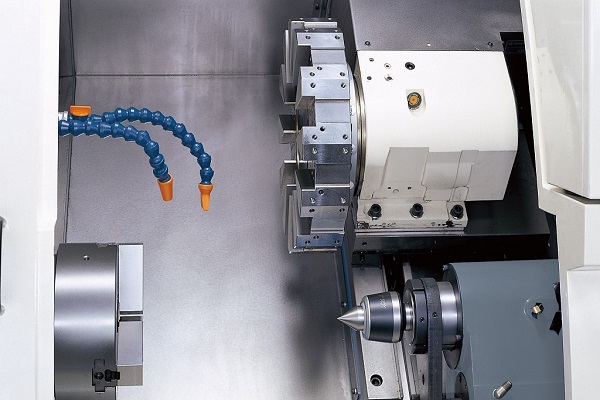

3-Jaw Chuck, Turret and Tailstock

3-Jaw Chuck – Provides secure and precise clamping for a wide range of workpiece sizes, ensuring stable machining even under heavy cutting conditions.

Turret – High-rigidity turret with rapid indexing for efficient multi-tool operations, reducing setup time and increasing productivity.

Tailstock – Robust tailstock for supporting long workpieces, enhancing machining accuracy and stability during turning operations.

Turret – High-rigidity turret with rapid indexing for efficient multi-tool operations, reducing setup time and increasing productivity.

Tailstock – Robust tailstock for supporting long workpieces, enhancing machining accuracy and stability during turning operations.

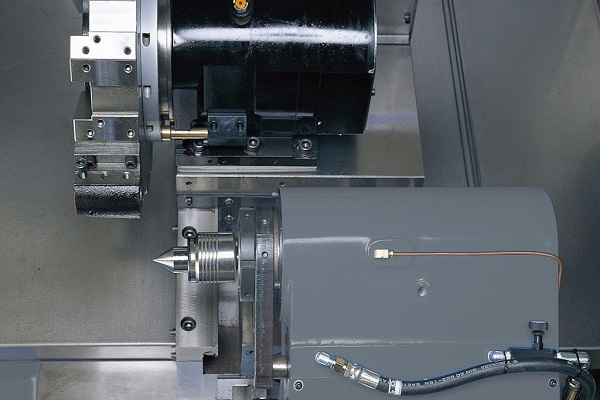

Programmable Tailstock

The SH series can be equipped with a programmable tailstock for automated positioning and support of long workpieces. This feature reduces manual adjustments, improves setup efficiency, and ensures consistent accuracy during turning operations, especially in high-volume production.

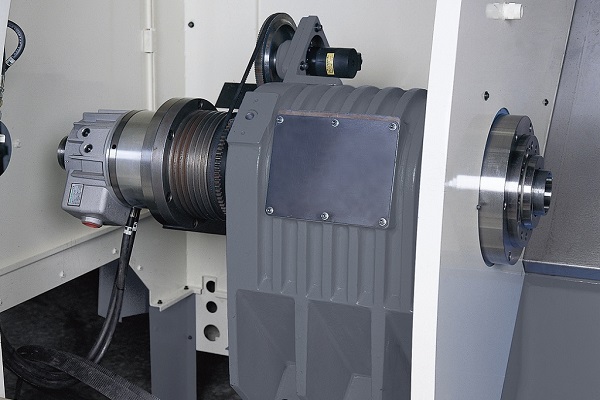

Precision Spindle

The SH features a high-precision spindle engineered for exceptional accuracy, stability, and durability under heavy cutting loads. Its robust construction minimizes vibration, ensures superior surface finish, and maintains consistent performance in demanding machining applications.

| Model | Unit | SH-75/90 | SH-75L/90L | SH-75M/90M | SH-75ML/90ML |

|---|---|---|---|---|---|

| Max. swing over bed | mm | Ø670 | Ø670 | Ø670 | Ø670 |

| Max. turning diameter | mm | Ø520 | Ø520 | Ø400 | Ø400 |

| Max. turning length | mm | 610 | 1100 | 540 | 1100 |

| Spindle max. bar capacity | mm | Ø73 / Ø89 | Ø73 / Ø89 | Ø73 / Ø89 | Ø73 / Ø89 |

| Spindle bore diameter | mm | Ø87 / Ø102 | Ø87 / Ø102 | Ø87 / Ø102 | Ø87 / Ø102 |

| Spindle nose | - | A2-8 | A2-8 | A2-8 | A2-8 |

| Spindle speed range | rpm | 45~3000 | 45~3000 | 45~3000 | 45~3000 |

| Spindle motor | kw | 18.5 / 22 | 18.5 / 22 | 18.5 / 22 | 18.5 / 22 |

| Number of tool station | - | 12/10 | 12/10 | 12 | 12 |

| Max. stroke X-axis | mm | 270 | 270 | 270 | 270 |

| Max. stroke Z-axis | mm | 650 | 1150 | 550 | 1050 |

| Rapid traverse X-axis | m/min | 16 | 16 | 16 | 16 |

| Rapid traverse Z-axis | m/min | 20 | 20 | 20 | 20 |

| Machine slant design | deg | 45˚ | 45˚ | 45˚ | 45˚ |

| Slideway type | - | Square guideway | Square guideway | Square guideway | Square guideway |

| Tailstock taper | - | MT5 | MT5 | MT5 | MT5 |

| Spindle hydraulic chuck | inch | 10" / 12" | 10" / 12" | 10" / 12" | 10" / 12" |

| Turning tool diameter | mm | □32 | □32 | □32 | □32 |

| Boring tool diameter | m | Ø50 | Ø50 | VDI 50 | VDI 50 |

| Driven tool motor power /30min | kw | - | - | 7.5 | 7.5 |

| Hydraulic pump motor | kw | 1.5 | 1.5 | 1.5 | 1.5 |

| Lubrication motor | w | 75 | 75 | 75 | 75 |

| Power requirement | kva | 44 | 44 | 56/62 | 56/62 |

| Coolant tank capacity | L | 190 | 190 | 190 | 190 |

| Machine dimensions(LxWxH) | mm | 3209x1990x2200 | 3965x1990x2200 | 3290x1990x2200 | 3965x1990x2200 |

| Weight | kg | 6350/6380 | 7510/7530 | 6400/6430 | 7560/7590 |

Standard Accessories

- Cutting coolant

- Splash guard

- Hydraulic turret

- Tailstock

- Chuck air blow

- Tools and tool box

- Wedge block

- Leveling pads

- Heat exchanger

- Operation manual

- Power turret (For SH-75M/75ML/90M/90ML)

- C axis (For SH-75M/75ML/90M/90ML)

Optional Accessories

- Tool presetter

- Chip conveyor and cart

- Parts conveyor

- Parts catcher

- Voltage stabilizer

- Transformer

- CE certification

This site uses cookies to improve your browsing experience. we'll assume you're OK to continue. If you want to read more about this, please check PRIVACY thank you.

Confirm